Two weeks ago, the name ‘Michter’s’ was reunited with a tangible piece of that storied distillery’s past, the barrel-a-day distillery made in 1976, which since 2011 has been on the outskirts of Cleveland, Ohio making bourbon, rye, and apple brandy at the Tom’s Foolery Distillery.

“It’s more distilling capacity than I need,” says Tom Herbruck about selling the equipment to Michter’s. “This will allow us to get back to our original plan of staying very small.” Tom’s Foolery is moving soon, to a farm where they already grow grain. They will keep making whiskey and other spirits, but on a smaller scale.

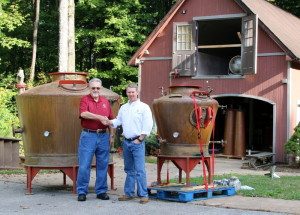

The once and future Michter’s still and small fermenters, loaded up

M1 will be stored at Michter’s Shively distillery until downtown is ready. Fort Nelson is a few blocks from the Evan Williams Experience, which has had a similar small distillery in operation for about two years. Others are in the works for Jim Beam and Old Forester. Two larger distilleries, Peerless and Copper & Kings, are just outside the downtown area.

The Michter’s equipment “is going to a place where a lot of people will get to see it and enjoy it,” says Herbruck.

He’s talking about the Michter’s visitors center that is being built in the Fort Nelson Building on Louisville’s ‘Whiskey Row.’ Restoration work on the beautiful, circa 1890 building has been slow because of structural problems discovered only after Michter’s bought it. Now completion is almost in sight, according to Michter’s President Joe Magliocco. The plan is to install and run the still, what Michter’s is calling ‘M1,’ at the Fort Nelson attraction.

On hand in Ohio to oversee the transfer were members of the Sherman family, whose Vendome Copper and Brass Works in Louisville designed and built the system for Michter’s 39 years ago. They refurbished it for Tom’s Foolery in 2011.

According to the Shermans, M1 was the first all-pot-still distillery built in the United States after Prohibition. Essentially, it was the original American micro-distillery. It consists of two alembic pot stills, three fermenters, a mash cooker, condenser, and all associated tanks and other accessories. The beer still has a capacity of 550 gallons. It is called ‘barrel-a-day’ because it can produce about 50 gallons of distillate per run.

In 1976, the distillery in Schaefferstown, Pennsylvania was struggling. The entire American whiskey industry was in the doldrums, with sales down across the board. Companies were consolidating and distilleries were closing. All of the other whiskey distilleries in Pennsylvania were gone or would be soon. The industry was dying.

Established in 1753, Schaefferstown had a good claim as America’s oldest continuously operating whiskey maker. The distillery had many different names over the years but was always at the same location. It officially became Michter’s in 1973. American history was hot in 1976 with the American bicentennial celebrations and Michter’s, located in tourist-rich ‘Pennsylvania Dutch’ country, was by then hanging on more as a tourist attraction than a whiskey maker.

Because business was so bad, the stills at Michter’s ran for only a few months every year. Tourists who came to the distillery expecting to see whiskey being made were frequently disappointed. Thus the idea for the barrel-a-day distillery was born. As a pot still system, it was more like the pre-Prohibition distilleries that had been at the site than the wholly modern Michter’s plant that was there then. It would be human scale and easier to understand, and as a batch system it could easily be run every day during tourism hours at minimal expense.

Naturally, the demonstration distillery was opened with great hoopla and did create a significant though short-lived increase in visitors. Uniquely in Pennsylvania, Michter’s had special permission from the state’s Liquor Control Board to sell its whiskey in the distillery gift shop. More tourism meant more whiskey sales too.

Willie Pratt (Michter’s) and Tom Herbruck (Tom’s Foolery)

Michter’s shut down in February of 1990. So catastrophic was the final collapse that the owners simply vanished, abandoning the property, equipment, and aging whiskey. They also abandoned the intellectual property, including the Michter’s name, which was claimed a few years later by Chatham Imports. Since then, the new Michter’s has built a fine reputation as a non-distiller producer (NDP) with a well-regarded portfolio of mostly high-end bourbons and ryes sourced from unidentified distilleries.

Unlike most NDPs, Michter’s is making the transition to distiller. The brand new Michter’s distillery in the Louisville suburb of Shively is now producing. Its first barrels were filled during the last week of August. The Shively distillery is large by micro standards, but small compared to Wild Turkey or Jim Beam. It will, of course, be years before anything distilled there is sold.

Tom’s Foolery put away about 450 full-size barrels of bourbon and rye during the four years they ran M1. For proprietors Tom and Lianne Herbruck, that’s a lot. They believe it is the largest inventory of aging whiskey in Ohio. All of it was made in open fermenters using the sour mash process, exactly as the system was designed to do in 1976. (Most modern micro-distillers don’t use sour mash.) The Herbrucks hope to sell that whiskey in a few years as bottled-in-bond bourbon and rye.

Back to the history of M1 itself. It sat unused like everything else at Schaefferstown while the county government sorted things out. In 1996, the just-retired master distiller at Jim Beam, David Beam, bought it and moved it to Bardstown, Kentucky. He put it on display next to a motel he owned. He and his sons talked about hooking it up and starting a micro-distillery, but it never happened. Beam sold the motel and in 2011 sold the distillery equipment to the Herbrucks. He and other family members made several trips to Ohio to get it going. He was honored at the first release of Tom’s Foolery Ohio Straight Bourbon Whiskey in Cleveland in November of 2014. He died on June 29 this year.

“It worked out nicely for the time that I had it,” says Herbruck. “I’ve grown attached to the equipment. There’s that sentimental value, a little bit of sadness. It’s like sending a child off to college.” Herbruck’s oldest, Emily, is a freshman at Miami University in Oxford this fall. “I know it’s the right thing to do.”